The Sulzer Z40/48 is a robust and efficient medium-speed diesel engine, commonly used in marine and power generation applications. One of its critical components is the cylinder cover, specifically identified by the code number K 27101. This cylinder cover plays a vital role in maintaining the engine's performance and reliability by sealing the combustion chamber, thus ensuring optimal compression and efficient fuel combustion. The precision-engineered K 27101 cover is designed to withstand the high pressures and temperatures within the engine, contributing significantly to the engine's longevity and operational efficiency. Regular inspection and maintenance of the cylinder cover are essential to prevent wear and ensure the engine continues to perform at its best.

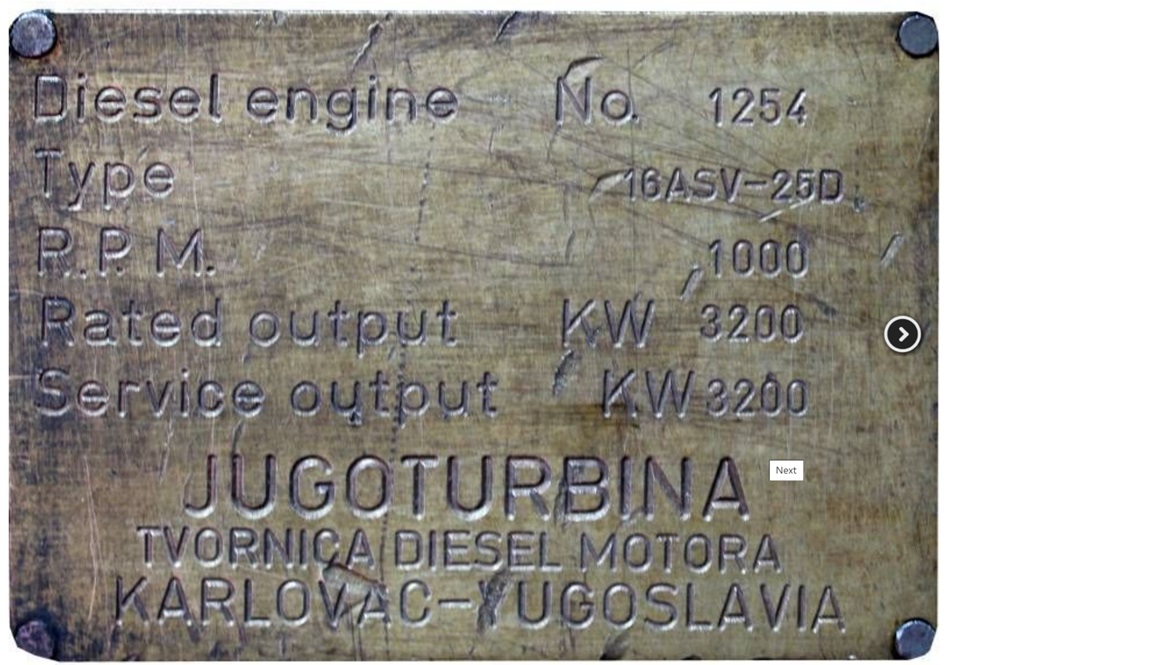

The Sulzer 16 ASV 25D, serial number 1254, is a robust diesel engine model manufactured in 1985. With an impressive horsepower of 4290 HP and an output of 3200 kW, this engine operates at 1000 RPM. It features a 250 mm cylinder bore and a 300 mm piston stroke within its 16-cylinder V-engine configuration. Enhanced by a BBC Turbocharger VTR 251-2N, specification GB7NT, it ensures high performance and efficiency. Classified under DNV, this engine was produced under license by JUGOTURBINA TVORNICA DIESEL MOTORA in Yugoslavia, making it a testament to precision engineering and durable construction from that era.

The Sulzer 16 ASV 25D, serial number 1254, is a robust diesel engine model manufactured in 1985. With an impressive horsepower of 4290 HP and an output of 3200 kW, this engine operates at 1000 RPM. It features a 250 mm cylinder bore and a 300 mm piston stroke within its 16-cylinder V-engine configuration. Enhanced by a BBC Turbocharger VTR 251-2N, specification GB7NT, it ensures high performance and efficiency. Classified under DNV, this engine was produced under license by JUGOTURBINA TVORNICA DIESEL MOTORA in Yugoslavia, making it a testament to precision engineering and durable construction from that era.

The Sulzer ZA40S engine, renowned for its robust performance and reliability in marine and power generation applications, features a critical component known as the rack for the fuel injection pump, identified by the code number KS 55006. This rack is integral to the precise regulation of fuel delivery, ensuring optimal combustion and efficiency. Proper maintenance and adjustment of the fuel injection pump rack are crucial, as any deviations can lead to suboptimal engine performance, increased fuel consumption, and potential mechanical failures. Utilizing genuine parts like the KS 55006 rack, coupled with professional maintenance, ensures the Sulzer ZA40S engine operates at its peak efficiency, delivering consistent power and longevity.

Inadequate, non-professional, or inexperienced maintenance significantly accelerates the aging and degradation of diesel engines. Poor maintenance leads to faster wear, undetected faults, and decreased reliability due to improper repairs or adjustments. Using a single engine type for a fleet can mitigate these issues by simplifying training, reducing maintenance costs, standardizing procedures, and allowing technicians to develop deep expertise in maintaining that specific engine type. This approach enhances operational efficiency, reliability, and cost-effectiveness, ensuring the longevity and performance of the engines.

The Sulzer 18ZAV40S is one of the leading marine engines, known for its durability and efficiency in harsh working conditions. A key component that contributes to this outstanding performance is the connecting rod lower bearing, with the code number KS 33201. This bearing is specially designed to withstand high pressures and vibrations within the engine, ensuring the stable and reliable operation of the connecting rod. Made from high-quality materials, KS 33201 provides long-lasting protection and minimizes wear, which is vital for maintaining optimal engine performance. Regular maintenance and timely replacement of this bearing are crucial for the longevity and reliability of the Sulzer 18ZAV40S engine, allowing it to continue delivering top efficiency and reduced emissions, contributing to economical and environmentally friendly navigation.

Sulzer ASL25 engines are known for their reliability and efficiency, and a key element that ensures their optimal functionality is the oil pressure regulation valve with the code number H 85700. This valve plays a vital role in maintaining stable oil pressure within the engine, which is crucial for the longevity and performance of the engine. Made from high-quality materials, the H 85700 valve ensures wear resistance and durability under high operating pressures. Regular inspection and maintenance of this valve can prevent potential failures and ensure the smooth operation of the engine, making it an indispensable part of the Sulzer ASL25 engine.

The Sulzer ASL25 engine stands out as a robust and efficient solution for marine and industrial applications. Renowned for its durability and superior performance, the ASL25 is engineered to operate under the harshest conditions, ensuring reliable power delivery. One of the key components ensuring its optimal functionality is the H81214 thermometer. This critical instrument accurately monitors engine temperature, safeguarding against overheating and ensuring the engine operates within safe parameters. Regular checks and maintenance of the H81214 thermometer are essential, as it plays a pivotal role in prolonging the engine’s lifespan and maintaining peak performance, ultimately contributing to cost-effective and efficient operations.

The crankshaft for Sulzer ASL25/30 engines is a vital component that ensures stable engine operation. It is made from premium materials that enable long-lasting performance and wear resistance. Regular maintenance of the crankshaft and the use of quality spare parts can extend the engine's lifespan and ensure optimal performance. Proper care of the crankshaft is crucial for the safe and efficient operation of the marine engine.

The SULZER AL25-30 is a reliable and efficient marine engine used in various applications. Its design allows for high efficiency and long-lasting operation. The AL25-30 is known for its robustness and ability to withstand harsh working conditions, making it ideal for use in commercial ships. Maintaining this engine is relatively straightforward, and its technology ensures reduced emissions and fuel consumption, contributing to economical operation.

The valve guide for Sulzer Al20/24 engines is a crucial component that ensures the proper guiding of the valves within the engine. This component is made from high-quality materials to withstand high temperatures and pressures inside the engine. Regular maintenance and replacement of valve guides can significantly improve engine performance and reduce the risk of failures. High-quality valve guides contribute to more efficient engine operation and reduced emissions of harmful gases.